FUTURA®

The powerful best seller band saw blade

- Product level 3

- Trapezoid tooth

- Solid materials

- Band width 27 x 0.9 - 80 x 1.6mmBand width 1-1/16 x 0.035 - 3-1/8 x 0.063 Inch

has been added to the watchlist.

View watchlisthas been removed from the watchlist.

View watchlistFUTURA® — The powerful best seller band saw blade

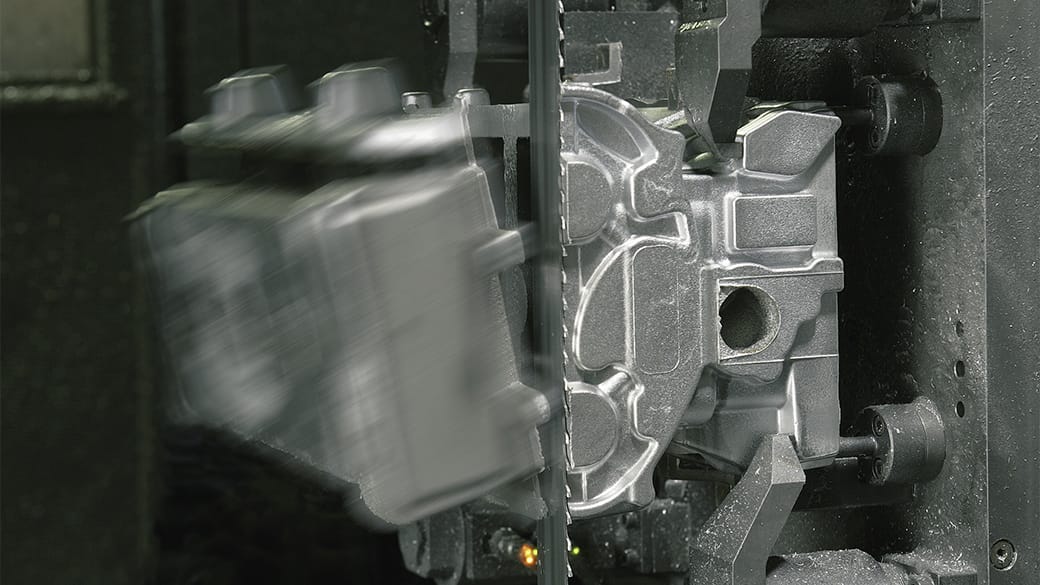

On modern band sawing machines suitable for carbide, FUTURA® unleashes its full potential, especially for multiple cuts on structural, case-hardened, quenched and tempered, and carbon steels.

On modern carbide-suitable band sawing machines, FUTURA® unleashes its full potential, especially for multiple cuts on structural, case-hardened, tempering, and carbon steels. Thanks to these benefits, the FUTURA® is suitable for customers with excellent standards.

Application Range

Application

- Case-hardening,temperingandtoolsteels

- Suitable for multiple cuts in the material mix

Advantages

- Very high cutting performance and thus productivity

- High wear resistance and thus long lifetime

- Very smooth and quiet running, low cutting forces and straight cuts

Features

- Polished trapezoid tooth with positive rake angle

- Optimized chip division

The backing material for the carbide bodies ensures a very long lifetime of the FUTURA® band saw blade thanks to its excellent continuous operation properties.

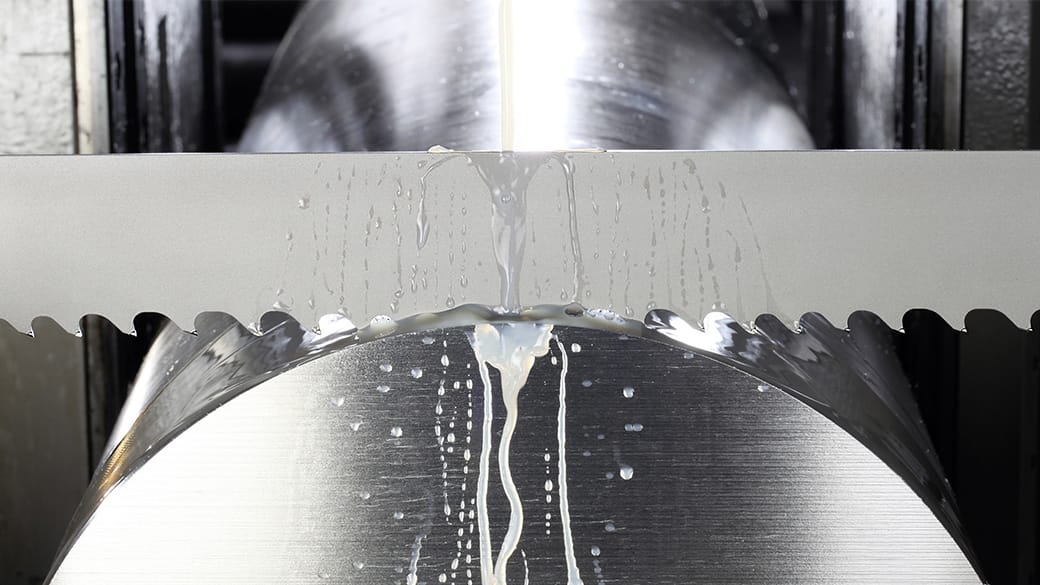

The trapezoidal tooth geometry is created in several high-precision steps on computer-controlled sanding machines and enables high cutting rates with low cutting forces. With a positive rake angle and powerful chip division, FUTURA® produces high surface quality and straight cuts.

A band saw blade with a history

Back in the early 1990s, WIKUS revolutionized the world of steel cutting with carbide-tipped band saw blades with the launch of the FUTURA® product. The carbide band saw blade FUTURA® at that time has developed into a whole high-performance product family for a wide variety of sectors and materials.

Dimensions

Tooth pitch in ZpZ

| Width x thickness | |

|---|---|

| mm | Inch |

| 27 x 0.90 | 1-1/16 x 0.035 |

| 34 x 1.10 | 1-3/8 x 0.042 |

| 41 x 1.30 | 1-5/8 x 0.050 |

| 54 x 1.30 | 2-1/8 x 0.050 |

| 54 x 1.60 | 2-1/8 x 0.063 |

| 67 x 1.60 | 2-5/8 x 0.063 |

| 80 x 1.60 | 3-1/8 x 0.063 |

Contact length[mm][Inch] | |

| 3-4 | 2-3 | 1.7-2 | 1.4-2 | 1.2-1.6 | 1-1.4 | 0.85-1.15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T | T | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T | T | T | T | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T | T | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T | T | T | T | T | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T | T | T | T | T | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| T | T | T | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80-1703.1-6.7 | 150-3005.9-11.8 | 250-3709.8-14.6 | 290-55011.4-21.6 | 400-75015.7-29.5 | 500-100019.7-39.4 | 700-140027.6-55.1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Case-hardening steels, spring steels and ball-bearing steels

- Nitrided steel, high-speed steel and tool steel

- Construction, deep-drawn and machining steels

- Carbon steels, and quenched and tempered steels

- Cast iron

has been added to the watchlist.

View watchlisthas been removed from the watchlist.

View watchlistAny more questions?

The experts of our Technical Competence Center are happy to help you answer further technical questions connected to band selection and use.